Products

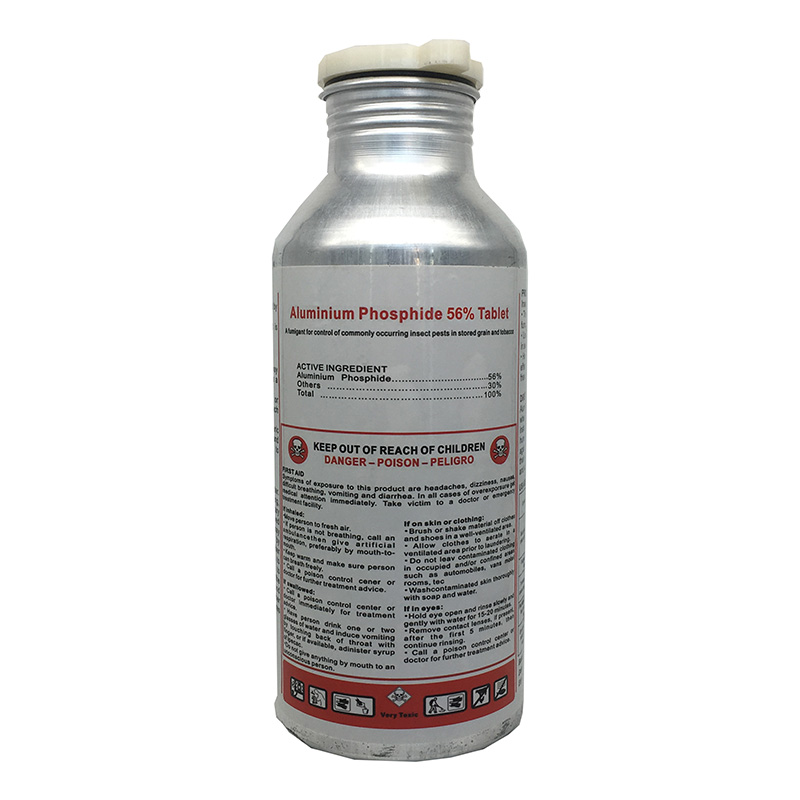

POMAIS Pesticide Aluminum Phosphide 56%TB 57%TB

Introduction

Aluminum Phosphide is a highly toxic inorganic compound with the chemical formula AlP, which can be used as a wide energy gap semiconductor and fumigant. This colorless solid usually appears as gray-green or gray-yellow powder on the market because of impurities produced by hydrolysis and oxidation.

Related reading: Zinc Phosphide vs Aluminum Phosphide

| Item | Specification / Notes |

|---|---|

| Active Ingredient | Aluminum Phosphide (AlP) |

| Active Content | 56% TB or 57% TB |

| Dosage Form | Tablet (TB), solid fumigant |

| Appearance | Grey-green to grey-yellow tablets; consistent color tone per batch |

| Odor | Characteristic; released gas has strong, pungent odor warning properties |

| Shelf Life | Typically 2 years in original, sealed packaging under recommended storage |

| Storage | Cool, dry, well-ventilated area; protected from moisture; keep containers tightly closed |

| Documents | COA, MSDS; dossier support where applicable |

Key Features & Benefits

-

High-efficacy fumigation for storage pests in sealed environments when used according to label and local regulations.

-

Tablet convenience: measured unit dose, straightforward handling within compliant operating procedures.

-

Stable supply chain: standardized tablet weight and packaging to streamline inventory and application logistics.

-

OEM-ready: multi-language labels, anti-counterfeit features, and customizable packaging sizes for different markets.

-

Documented QC: batch HPLC/assay records, packaging integrity tests, and storage stability support.

Formulation & Tablet Options

| Option | Typical Spec | Notes |

|---|---|---|

| Strength | 56% TB | Mainstream commercial grade |

| Strength | 57% TB | Alternate high-content tablet for markets requiring this label strength |

| Tablet Weight | 3.0 g per tablet (other weights on request) | Standardized tablet weight improves operational planning |

| Tablet Color | Grey-green / grey-yellow | Color variation due to controlled manufacturing and oxidation profile |

| Packaging Materials | Aluminum bottles / HDPE bottles / composite cans | Moisture-resistant, tamper-evident options available |

Mode of Action

Aluminum phosphide is usually used as a broad-spectrum fumigation pesticide, mainly used to fumigate and kill storage pests of goods, various pests in spaces, grain storage pests, seed grain storage pests, outdoor rodents in caves, etc. . After aluminum phosphide absorbs water, it will immediately produce highly toxic phosphine gas, which enters the body through the respiratory system of insects (or mice and other animals) and acts on the respiratory chain and cytochrome oxidase of cell mitochondria, inhibiting their normal respiration and causing death. . In the absence of oxygen, phosphine is not easily inhaled by insects and does not show toxicity. In the presence of oxygen, phosphine can be inhaled and kill insects. Insects exposed to high concentrations of phosphine will suffer from paralysis or protective coma and reduced respiration. Preparation products can fumigate raw grains, finished grains, oil crops, dried potatoes, etc. When fumigating seeds, their moisture requirements vary with different crops.

Application scope

In sealed warehouses or containers, all kinds of stored grain pests can be directly eliminated, and mice in the warehouse can be killed. Even if pests appear in the granary, they can also be killed well. Phosphine can also be used to treat mites, lice, leather clothing, and down moths on items in homes and stores, or to avoid pest damage. Used in sealed greenhouses, glass houses, and plastic greenhouses, it can directly kill all underground and above-ground pests and mice, and can penetrate into plants to kill boring pests and root nematodes. Sealed plastic bags with thick texture and greenhouses can be used to treat open flower bases and export potted flowers, killing nematodes underground and in the plants and various pests on the plants.

-

Grain silos and warehouses: sealed storage fumigation programs run by trained, licensed personnel.

-

Sealed containers and stacks: controlled conditions after structural sealing and monitoring protocols.

-

Rodent burrows or specialized settings: only where permitted by local regulation and label.

Important: This is a hazardous fumigant. No operational instructions or dosage guidance are provided here. Always follow the registered product label and local regulations, and ensure only trained, licensed professionals plan and conduct fumigation.

Safety & Compliance

-

Produces highly toxic phosphine gas upon exposure to moisture.

-

Use is restricted to approved sites and conditions; strictly follow label and local regulatory requirements.

-

Only trained, licensed personnel should handle, apply, monitor, and aerate fumigations.

-

PPE and gas monitoring are mandatory; maintain exclusion zones and verify safe re-entry levels before access.

-

Protect non-target organisms (humans, pets, livestock, pollinators, aquatic life) and prevent environmental release.

-

Store away from food, feed, and moisture; never open containers in humid environments.

Packaging & OEM Services

Standard Pack Sizes (reference options):

-

Tablets per container: configured to client spec (e.g., 300 g, 1 kg per bottle; other sizes available)

-

Outer carton: strength-rated for export with moisture barrier and clear hazard labeling

-

Sealing & Closures: induction-seal or gasketed lids; tamper-evident rings

-

Labeling: English, Arabic, Russian, Spanish, French and others; QR codes/serials; anti-counterfeit features

-

Artwork: brand CI alignment; compliance icons; handling pictograms; storage and hazard statements

-

Lead Time: typically 20–30 days after specification and artwork lock (subject to capacity)

-

MOQ: aligned to bottle size and destination; shared at quotation stage

Quality Control & Stability

-

Assay & Identity: batch testing with documented COA.

-

Physical Integrity: tablet hardness and friability within internal standards; low dusting.

-

Packaging Tests: drop and vibration simulations; 24-hour inverted-leak checks for sealed containers.

-

Stability: retained samples and periodic checks under recommended storage conditions.

-

Traceability: batch codes on primary and secondary packaging; documentation archived per policy.

Procurement Guidance (How to Specify in RFQ)

-

Strength: 56% TB or 57% TB.

-

Tablet Weight & Count: e.g., 3.0 g tablets; number of tablets per container.

-

Packaging: bottle material and size, closure type, outer carton spec.

-

Label Languages: required languages and any regulatory text formats.

-

Branding & Security: artwork, anti-counterfeit (QR/serial), hazard pictograms.

-

Destination Market: for compliance checks and document formatting.

-

Samples & Documents: pilot samples, COA/MSDS templates, and any dossier assistance.

FAQ

Q1. What is the difference between 56% TB and 57% TB?

Both are aluminum phosphide tablets; the label strength differs. Choice depends on local registrations, customer preference, and inventory alignment.

Q2. Can you provide multi-language labels and customized packaging?

Yes. We support multiple languages, anti-counterfeit elements, and a range of bottle sizes and outer cartons.

Q3. What is the typical shelf life?

Generally 24 months in unopened, original packaging under recommended storage conditions.

Q4. Do you provide usage instructions or dosage on the website?

No. For safety and compliance, operational instructions and dosage are provided only on the registered product label and to trained, licensed professionals according to local regulations.

Q5. Can you support registration or tender documents?

Yes. We can provide COA, MSDS, product data sheets, and coordinate dossier materials as available for the destination market.

Why Choose Us

-

Focused supply capability for 56% TB/57% TB with stable output and consistent tablet quality.

-

OEM excellence: small-pack flexibility, brand-aligned artwork, and multi-language compliance.

-

Tight QC from assay to packaging integrity; retained samples and traceability.

-

Export experience across climate zones and regulatory frameworks, with responsive documentation support.

Share your target strength (56% TB / 57% TB), tablet weight & pack size, label languages, and destination market. We will return a tailored spec sheet, COA/MSDS set, sample plan, and commercial offer aligned to your registration and delivery timeline.